NAVIGATION

- Inert Gas GLovebox

- Gas purification systems

- Glovebox Industry applications&Solutions

- Feedthroughs & Viewports

- Glovebox Accessories

- Plasma/UV-Zone Cleaners

- Ultrasonics/Water Circulator

- Film Coating

- Electronic Packages

- Battery R&D Equipment

- R2R Flexible Electronics Printing

LATEST NEWS

- Made in Space – 1st ISS 3D Printer

- M-Braun Glovebox System Operation Procedur

- Stainless steel glove box

- NREL test helps make moisture barriers bet

- Organic/inorganic sulfur may be key for sa

- Grant supports development of next-generat

CONTACT US

- Add: RM 1802B-A6 Fortress Tower 250 Kings RD North Point HongKong

- Tel: +86 010 8499 8901

- Fax: +86 010 8499 8901

- Email: adahan@foxmail.com

ONLINE STORE

nXDS10i Scroll Pumps

- Product description: nXDS10i Scroll Pumps

Product introduction

nXDS improves on the original XDS pump technology by offering increased pumping speeds, combined with lower ultimate pressures, low power consumption and reduced noise. The gas ballast allows for pumping of condensable vapours, including water, solvents, dilute acids and bases. nXDS pumps feature the very latest in tip seal technology, giving a significantly longer life between tip seal changes.

nXDS-C has been modified so that it is more suitable for use on vapour handling processes and may be used in some applications involving corrosive substances. This chemically resistant version is fitted with Chemraz® internal valves and stainless steel fittings.

nXDS-R has the gas ballast blanked off so it cannot be accidently opened. This is useful for applications such as rare gas recirculation or gas recovery.

Features

- Advanced scroll-form and tip-seal technologies deliver best-in-class vacuum performance

- Quiet operation <57 dB(A) for minimal environmental impact

- Intelligent and easy to use control functions with simple operation

- Up to five year service interval for low cost of ownership

- Hermetically sealed for a lubricant-free vacuum environment

Applications

- Mass Spectrometry

- Electron Microscopy

- Sample Preparation

- Research and Development

- High Energy Physics

- Industrial

- Semiconductor

Technical Data

|

Nominal rotational speed |

1800 rpm |

|

Displacement |

12.7 m3h-1 / 7.5 ft3min-1 |

|

Peak pumping speed |

11.4 m3h-1 / 6.7 ft3min-1 |

|

Ultimate vacuum (total pressure) |

0.007 mbar / 0.005 Torr |

|

Minimum standby rotational speed |

1200 rpm |

|

Speed control resolution (percentage of full rotation speed) |

1% |

|

Pumping speed at minimum rotational speed |

7.5 |

|

Maximum continuous inlet pressure |

200 mbar |

|

Motor power 1-ph |

280 W |

|

Power connector 1-ph |

IEC EN60320 C13 |

|

Recommended fuse |

10A, 250Vac rms |

|

Weight |

25.8 kg / 57 lb |

|

Inlet flange |

NW25 |

|

Exhaust flange |

NW25 |

|

Noise level |

52 dB(A) |

|

Vibration at inlet flange |

< 4.5 mms-1 (rms) |

|

Leak tightness (static) |

< 1x10-6 mbar ls-1 |

|

Operating temperature range |

10 to 40 °C / 41 to 104 °F |

Specifications Table

|

Pump Model |

nXDS6i |

nXDS10i |

nXDS15i |

nXDS20i |

XDS35i |

|

Chemistry |

Standard |

Standard |

Standard |

Standard |

Standard |

|

Disp. CFM @ 60 Hz |

3.6 (6.2) |

6.7 (11.4) |

8.9 (15.1) |

13 (22) |

25 (43) |

|

Ult. Pressure Torr |

1.5 x 10-2 |

5 x 10-3 |

5 x 10-3 |

2.2 x 10-2 |

8 x 10-3 |

|

Motor HP (kW) |

0.35 (0.26) |

0.38 (0.28) |

0.4 (0.3) |

0.35 (0.26) |

0.8 (0.6) |

|

Inlet Flange |

KF25 |

KF25 |

KF25 |

KF25 |

KF40 |

|

Exhaust Flange |

KF25 |

KF25 |

KF25 |

KF25 |

KF25 |

|

Dimensions |

17 x 10.4 x 11.3 |

17 x 10.4 x 11.3 |

17 x 10.4 x 11.3 |

17 x 10.4 x 11.3 |

18.7 x 13.1 x 15.6 |

|

Weight lbs (kg) |

58 (26.2) |

57 (25.8) |

56 (25.2) |

56 (25.6) |

105 (48) |

|

Noise db(A) |

52 |

52 |

52 |

52 |

57 |

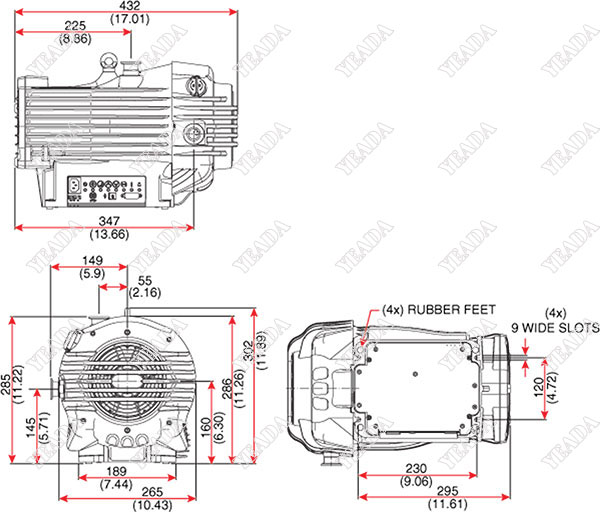

Dimensional Drawings